In this case study, Makalot shares what the benefits of DPC implementation is, their measurements on their Return of Investment, the framework of their DPC Process, among others.

Makalot made early investments on innovations in Digital Product Creation (DPC) beginning in 2006 that yield fruit today through lead time reduction, improved operational efficiency, and supply chain resilience.

By integrating Vizoo’s material scanning and other DPC technologies, Makalot minimizes physical sampling and waste, contributing to a more sustainable apparel production model.

Elly Cheng, Director of Digital Product Creation at Makalot, explains that adopting digital workflows has empowered the company to respond swiftly to changes, ensuring that production stays flexible and efficient. “Digital Product Creation allows us to streamline our supply chain, making it faster and more adaptive,” Cheng says. “This flexibility is crucial in today’s market, where consumer preferences can change rapidly. DPC enables us to quickly prototype, adjust, and finalize designs without the delays and waste associated with traditional methods.”

Key Points in the Study:

1. Success Factors. The success of implementing DPC as a competitive advantage is heavily influenced by the overall company’s strategic plan, quality of change management, the quality and reliability of technology providers, and the speed and the ability to integrate learning & feedback into the next iterations.

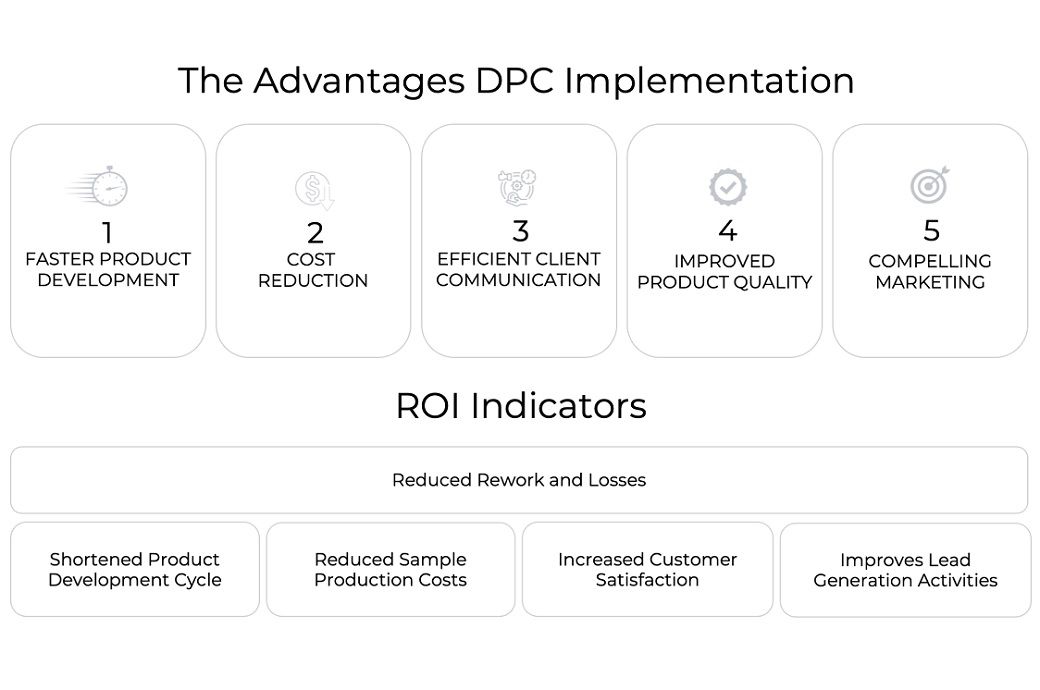

2. Measuring ROI. Selecting key performance indicators to measure the return on investment requires to have a holistic view of both short-term and long term KPI’s.

3. The Importance of Stakeholder Alignment. Makalot’s case is an interesting example of how seeking stakeholder buy-in from the very beginning of each project, aligning on purpose, needs and expectations determine the success and speed of the DPC project.

Note: The content of this press release has not been edited by Fibre2Fashion staff.

Fibre2Fashion News Desk (KD)